OUR EXPERTISE

25 YEARS IN THE CALCULATION OF STRUCTURE AND OUR EXTENSIVE KNOWLEDGE OF HIGH PERFORMANCE COMPOSITES, ALLOWS US TO MASTER THE COMPLETE FLOW OF DESIGN PROCESSES.

We accompany our clients from the very first steps of their project to their production and its use, passing by all the steps of analysis, calculation, drawings and hotline during construction.

Our approach involves going back to the basics of the engineering culture by providing a response regarding the feasibility of a project using ‘classic’ tools (analytical calculations, spreadsheets), before beginning more complex and costly calculations.

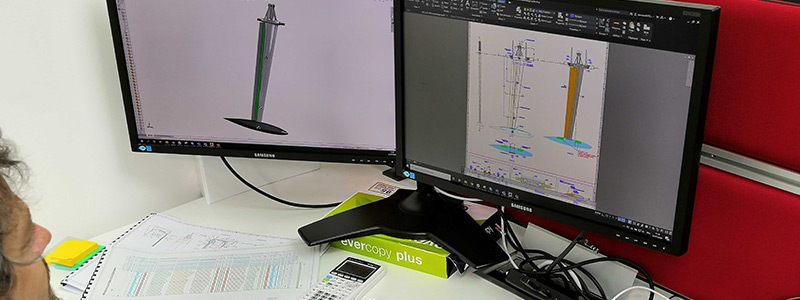

Secondly, if the project allows it, we can calculate and optimize the structure with our suit of stick finite element software (OPHELIA, SANDRA, ALAMO…). The use of stick modeling allows a gain in time compared to more complex solutions.

If the structure studied doesn’t fit with stick modeling or if the project needs a higher level of detail we realize a complete finite element model of the structure either in 2D shell or 3D volumetric.

This tried and tested approach allow us to optimize the calculation time and focus our energy on the important points of our clients projects.

Design

We step in the projects at their very beginning to bring our expertise to architects and other project holders. We can offer a fully optimized design based on our client specifications or the reuse and optimization of an existing design.

Our knowledge of materials and more specifically composite materials, as well as manufacturing processes, will ensure realistic proposals in terms of mechanical resistance.

Design to cost: Our Design skills, coupled with our research department and our knowledge of manufacturing processes, ensure an expertise that focuses on reducing production costs whilst maintaining the optimum quality of the product developed.

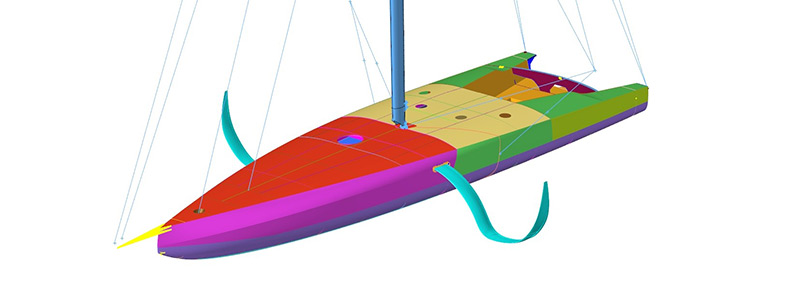

In our approach, the designers use sketches, drawings, 3D modelling tools and CAD tools to enable our clients to get some insight of the various opportunities available with their project and help them to validate the different options.

Engineering

We are design engineers specialized in mechanical engineering. Our expertise focus on carrying out mechanical studies and structure calculations using finite element analysis to simulate the behavior of products and processes. Structural calculation using finite element analysis in deformation-constraints simulates the behavior of a part or structure subject to the stresses of its environment.

Our studies allow to optimize the architecture of the model to comply with the design specifications in a very efficient cost/time ratio compared to the classic methodology of trial-manufacture iteration of a prototype thanks to the continuous development of our design and calculation tools.

We formalize our studies through detailed and clearly illustrated calculation notes.

Our expertise is widely recognized in the design and calculation of high performance structures in the domain of offshore racing, cruising as well as various industrial projects with high composite added-value : Renewable Energy (MRE, wind turbines), Marine industry, Aeronautics, Defence, Space…

FOLLOW UP DURING CONSTRUCTION

We maintain our expertise in the follow up of construction of our design thanks to a shared history with the manufacturing sites for projects of international dimension: Europe, USA, NZ, etc.

The realization of a product can be a complex operation, which puts the qualities of all those involved to the test.

Ensuring a fluid sequence of operations and comply with the technical drawings and specifications are essential to guaranty the quality of the products.

During this process, there are always unforeseen events, which occasionally require some form of modification to the initial drawings. Studies must then be completed in a short time to provide all the modifications drawings not to affect too much the yard schedule.

More than just advising, we also position ourselves as partners with the yards which we work with. As a result, it is our role to deal with the multiple hazards, by complying as much as possible to the initial specifications, to the deadlines and to the scheduled costs detailed in the contract.

DRAWINGS

The complementary skills of our teams enables us to take part in all steps of a project including providing detailed construction drawings of the pieces we design and calculate.

These drawings can either be principle drawings or detailed construction drawings that can be used directly by yards taking into account their fabrication process.

Testing

We can carry out test campaigns, normalized or specific, in order to qualify the stiffness, resistance and durability of composite laminates used in a project to optimize the design.