NOTRE EXPERTISE

25 ans dans le calcul de structure et notre connaissance très aboutie des composites hautes performances, nous permet de maîtriser le flux complet des process de conception.

Nos forces sont un accompagnement complet de nos clients du crayon à la réalisation et l’utilisation, en passant par toutes les phases d’analyse et de conception, de calcul et de dimensionnement, de réalisation de plans, de suivi de chantiers et d’essais.

Notre démarche est de remonter à la base de la culture de l’ingénieur en apportant une réponse rapide sur la faisabilité du projet grâce aux outils classiques (Calcul analytique, Feuille de calcul, Timoshenko, Roark), avant de commencer des calculs plus complexes et coûteux.

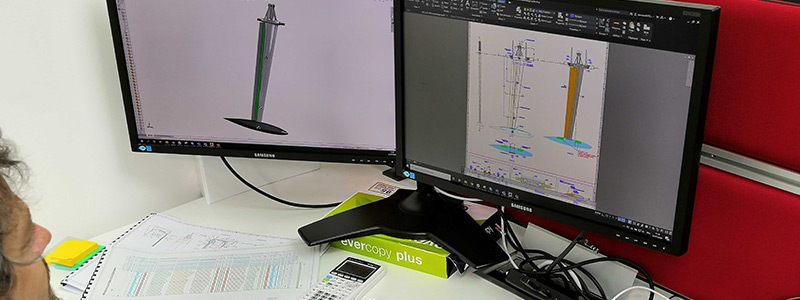

Dans un second temps, si la forme s’y prête, nous pouvons dimensionner et optimiser la structure avec notre suite d’outils élément finis poutre (OPHELIA, SANDRA, ALAMO). L’utilisation de la modélisation poutre permet de gagner du temps par rapport à une modélisation plus complexe.

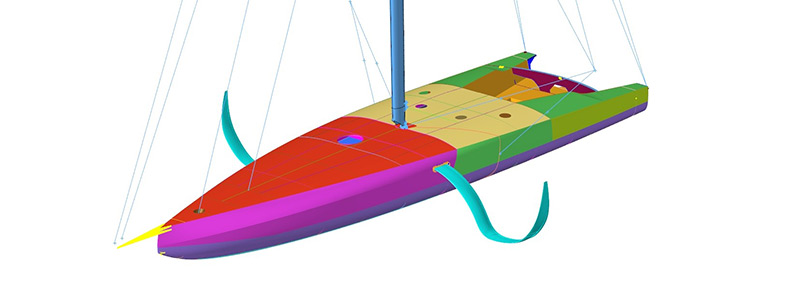

Si la structure ne permet pas une modélisation poutre, ou si le niveau détail souhaité est plus important, nous réalisons un modèle complet, élément finis coque 2D ou volumique 3D.

Cette démarche éprouvée nous permet d’optimiser les temps d’étude en concentrant notre énergie sur les points importants.

Design

Nous intervenons en amont des projets pour apporter notre expertise aux architectes et porteurs de projets. Nous pouvons proposer une conception complète optimale à partir d’un cahier des charges préalablement établi avec nos clients ou une reprise et optimisation d’un design existant.

Notre connaissance des matériaux, et plus spécialement des matériaux composites, ainsi que des process industriels assureront des propositions réalistes en termes de tenue mécanique.

Design to cost : Notre compétence Design, couplée à notre bureau d’études et nos connaissances des process industriels assure une expertise visant à réduire les coûts de production, tout en conservant la qualité optimale des produits développés.

Dans notre démarche, les designers utilisent des dessins, des esquisses, des outils de modélisation 3D, de CAO, pour permettre à nos clients de se projeter vers les différentes possibilités de leur projet et de valider plus rapidement et efficacement les différentes options envisagées.

Ingénierie

Nous sommes un bureau d’études spécialisé en ingénierie mécanique. Notre expertise porte sur la réalisation d’études mécaniques et de calculs de structures par éléments finis pour simuler le comportement de produits ou de process. Le calcul de structure par éléments finis simule en déformations-contraintes le comportement d’une pièce ou structure soumise aux sollicitations de son environnement.

Nos études permettent d’optimiser l’architecture du modèle afin de la rendre conforme au cahier des charges dans un compromis coût/délai extrêmement performant par rapport à la méthodologie classique d’itération fabrication-essai sur prototype mais aussi grâce aux outils que nous développons continuellement.

Nous formalisons nos études par la rédaction de notes de calculs détaillées et clairement illustrées.

Notre expertise est reconnue dans la conception et le calcul de structures hautes performances dans le domaine de la course au large, de la croisière mais également sur de nombreux projets industriels à forte valeur ajoutée composite : Energie Renouvelable (EMR, éolien), industrie Navale, Aéronautique, Défense, Spatial…

Suivi de chantiers

Nous entretenons notre expertise en suivi de chantiers grâce à une Histoire commune avec des chantiers de fabrication pour des projets d’envergure internationale : Europe, USA, NZ, etc…

Un chantier est une opération complexe, qui met à l’épreuve toutes les qualités des hommes qui y participent.

Le bon enchainement des multiples opérations, le respect des plans et des prescriptions techniques, sont indispensables à la bonne réalisation des travaux et donc à la qualité finale des pièces.

Pendant ce déroulement, il arrive toujours des éléments imprévus, nécessitant parfois une modification des plans. Les études doivent aussi être complétées pour fournir à temps tous les plans d’exécution.

Au-delà d’une mission de conseil, nous nous positionnons également comme partenaire des chantiers avec lesquels nous sommes amenés à collaborer. C’est donc notre rôle, que de faire face aux multiples aléas, en respectant, le plus possible, les obligations du cahier des charges, les délais et les coûts prévus au contrat.

Plans

La pluridisciplinarité de nos équipes nous permet de suivre nos projets jusqu’à fournir des plans de détails complets des pièces que nous concevons et que nous calculons.

Ces plans sont au choix des plans de principe ou des plans de construction détaillés directement utilisés par les chantiers en prenant compte de leur methodes de fabrication.

Testing

Nous menons des campagnes d'essais, normalisés ou spécifiques, de façon à qualifier en raideur, résistance et durabilité les matériaux et empilements composites utilisés dans le but d'optimiser les pièces calculées.